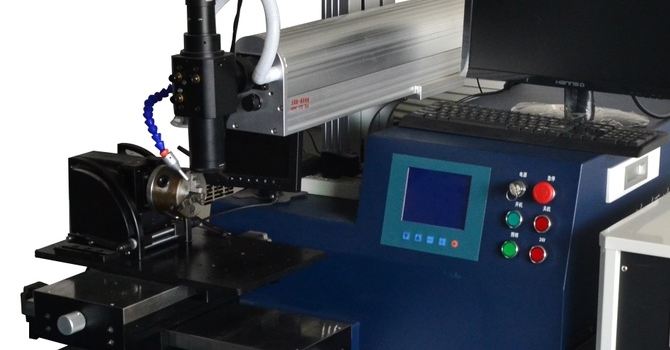

Automatic laser welder adopts manual+programming automatic dual-purpose worktable, electric focusing, 16 group precise waveform control; Suitable for mold repair, and welding all kinds of electronic products; The main advantages as follows:

(1) Electric regulate the lever of laser focus: It is convenient to regulate lever of laser rapidly through the manual button on the panel, which makes the laser focusing become simple and fast.

(2) positioning function of welding spot: It is through the red light direction to find the rough place of welding spot on the workpiece, aiming at the location of welding spot accurately by using Binocular high-magnification microscope observation.

(3) Electric regulating multiple size of scattering mirror (regulating the facula size).

(4) Manual control the movement of XY mobile worktable, optional automatic welding function of Electric control at the same time, which can realize automatic welding of products in high speed. .

(5) Integrative design, small size, compact structure, so it’s Convenient and practical.

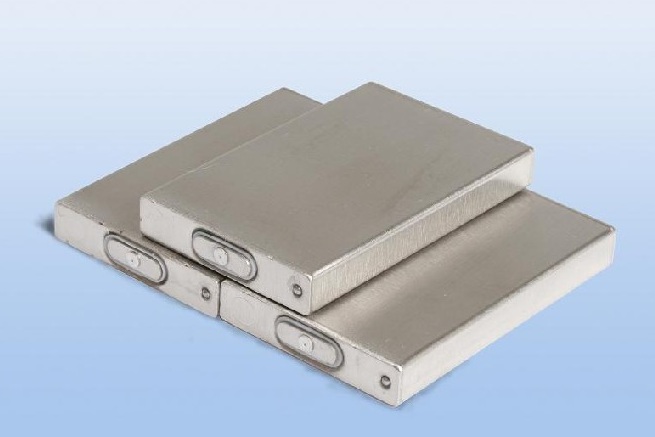

Application:

Apply to stainless steel, gold, silver, alloy, steel, flint equivalent material welding or dissimilar material welding, widely used in the cell phone battery, sensors, medical equipment, gifts, watches, electronic devices, sensors, precision machinery, communications etc.

Specification:

| MODEL

CONFIGURATION |

LS-Z-200W | LS-Z-400W |

| Focus lens | 100-150mm | |

| Beam expander mirror | 2-4times | |

| Laser rod | 7*145mm | |

| Laser cavities | 160mm gold-plated metal double light cavity | |

| Optical benches | The laser head can automatically expand, rotate, spot size is adjustable | |

| Position | Red light and cross microscope | |

| Electronic brake | With LCD light brake | |

| Cooling water machine | 1.5P | 3P |

| Movement workbench | Automatic and manual 2 d | |

| Frame | Aluminum alloy | |

| Rotary worktable | 360 degrees automatically rotating | |

Technology parameter:

| Model | LS-Z-200W | LS-Z-400W |

| Laser work material | Nd:YAG | |

| Maximum laser power (W) | 200 | 400 |

| Pulse frequency (Hz) | 1-100 | 1-500 |

| Maximum single pulse energy (J) | 90 | 150 |

| Rated Power (KW) | 4 | 6.5 |

| Observation system | microscope | |

| Control system | PLC/IPC | |

| Laser wavelength(nm) | 1064 | |

| Minimum spot size(mm) | 0.2 | |

| Pulse width(ms) | 0.1-20 | |

| Minimum welding molten pool(mm) | 0.15 | |

| Welding wire(mm) | 0.2-0.8 | |

| Welding depth (mm) | 0-2.5 | 0-3.5 |

| Power requirement | 9KW single phase 220VAC 15% 50HZ 30A above | 11KW three phase 380VAC 15% 50HZ 40A above |

| Working table stroke(mm) | 300×200×200 | |

Automatic laser welding machine