Feature:

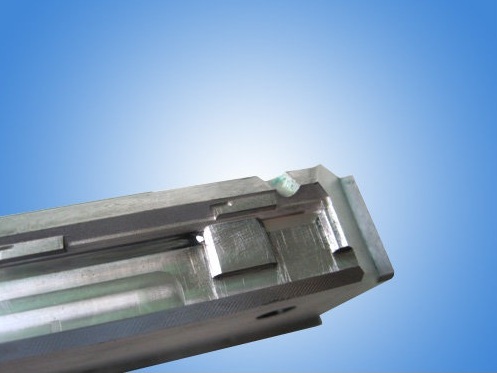

The optical can slide front and rear, manual lift, the optical mount can rotate 360 degrees, repair any side.

A flexible adjustment of direction, Angle and position welding, suitable for all kinds of mold repair welding.

For large mold, no need workbench, directly in the ground or forklift truck on die welding.

High power cold water chilling system keeps high power laser cavity, long time, stable high power welding.

Laser welding application:

Mold, machinery manufacturing industry | jewelry industry | digital products, mobile phones, computer industry | hardware, tools, instruments industry | car industry, sanitary kitchen electric vehicle industry | |energy lighting building materials industry and military, aviation aerospace industry |

The surface treatment industry | engineering machinery industry | electronic, electrical industry | battery industry

Observation system:

Equipped with the cross hairs special microscope magnification of 17.5X. Cross cursor Center and the laser spot center alignment (user adjustable). With high-speed electronic filter protection device to protect the operator eyes from laser injury, relieve the operator eye fatigue, improve work efficiency.

Welding materials:

Laser welding, can be used in stainless steel, alloy steel, aluminum, copper, gold, silver, chromium, nickel, titanium and so on many kinds of metal and alloy. Can also be nickel of copper, nickel-titanium, titanium-steel, titanium-molybdenum, brass, copper, low carbon steel-copper and so on many kinds of dissimilar metal welding between.

| Model | LS-M-W200W(400) |

| Maximum laser power | 200W, 400W |

| Maximum single pulse energy | 110J |

| Laser welding frequency | 0.5-40HZ |

| Laser welding depth | 0.1-3mm |

| Pulse width | 0.5-20ms |

| Spot size | 0.2-2mm |

| Laser welding wire | 0.2-0.8mm |

| workbench | Automatic reinforced workbench |

| Laser wavelength | 1.064um |

| Rated power | 3KW |

| Power required | single-phase 220 15% VAC 50HZ 30A |